Fabrication of custom build products

Handled materials

Drawing upon its unique diverse technical expertise and wealth of experience, MicroMedex B.V. handles a wide spectrum of high-performance materials, as demonstrated in our reference list.

Custom built products

Over 7 decades, MicroMedex B.V. has gained an extensive engineering expertise and fabrication know-how in high-integrity custom-built process equipment in heat- and corrosion resistant alloys used in numerous applications.

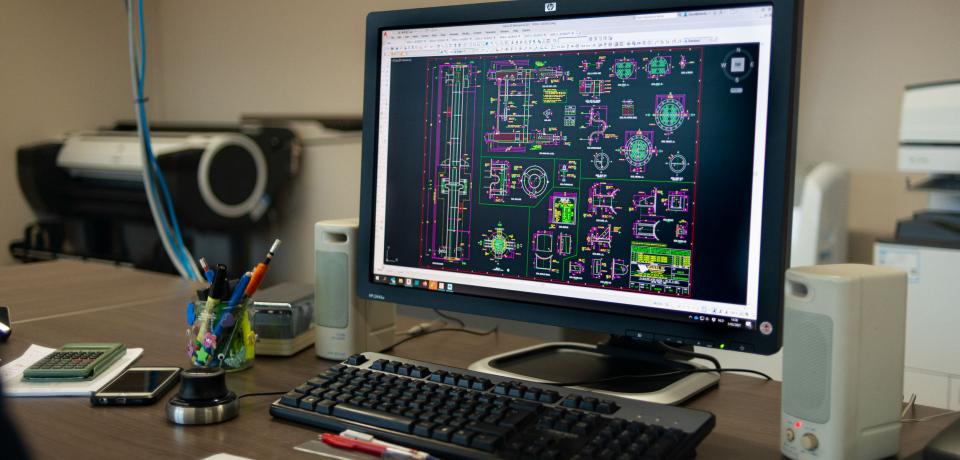

MicroMedex’ Design and Engineering Department operates a comprehensive system, using software of international repute for thermal rating, stress analysis, wind load and seismic resistance calculations, as applicable. Combined with our expertise, it enables MicroMedex’ engineers to optimise the equipment sizing and configuration and to maximize its cost-effectiveness.

Industries served

The equipment constructed by MicroMedex B.V. is used in numerous applications, particularly in the hydrocarbon and downstream industries, but also in other industries featuring aggressive atmospheres or operating in environments calling for heat or corrosion resistant materials.

Our working facilities

MicroMedex B.V. 15000m² spacious modern production facilities, out of which 6000m² covered area, include a range of varied and flexible cutting, forming and fabrication machines, comfortable lifting capacity up to 40 tons and latest state-of-the-art welding equipment. The latter comprises computer-controlled stations, automatic welding beams and orbital welding machines both for tube-to-tubesheet and for tube-to-tubes joints. With a welding capacity up to 4m diameter, we are well equipped for many different types of items.

Transportation

Based on a long lasting experience, our expediting department takes care of the timely delivery of the equipment to our customers, either by road, air- or seafreight, including customs clearance and providing all required shipping documents for ensuring a smooth import of the equipment at destination.

Repair solutions

As part of our strategy to strenghten the relation with our customers in different ways, we can arrange for the repairs of defective equipment at site or in our workshop, as feasible. Thanks to our large stock of various special alloy materials, and our flexible teams we can help and assist on short notice. The jobs can vary from solving welding issues to testing application to plugging/refurbishment of heat exchangers.